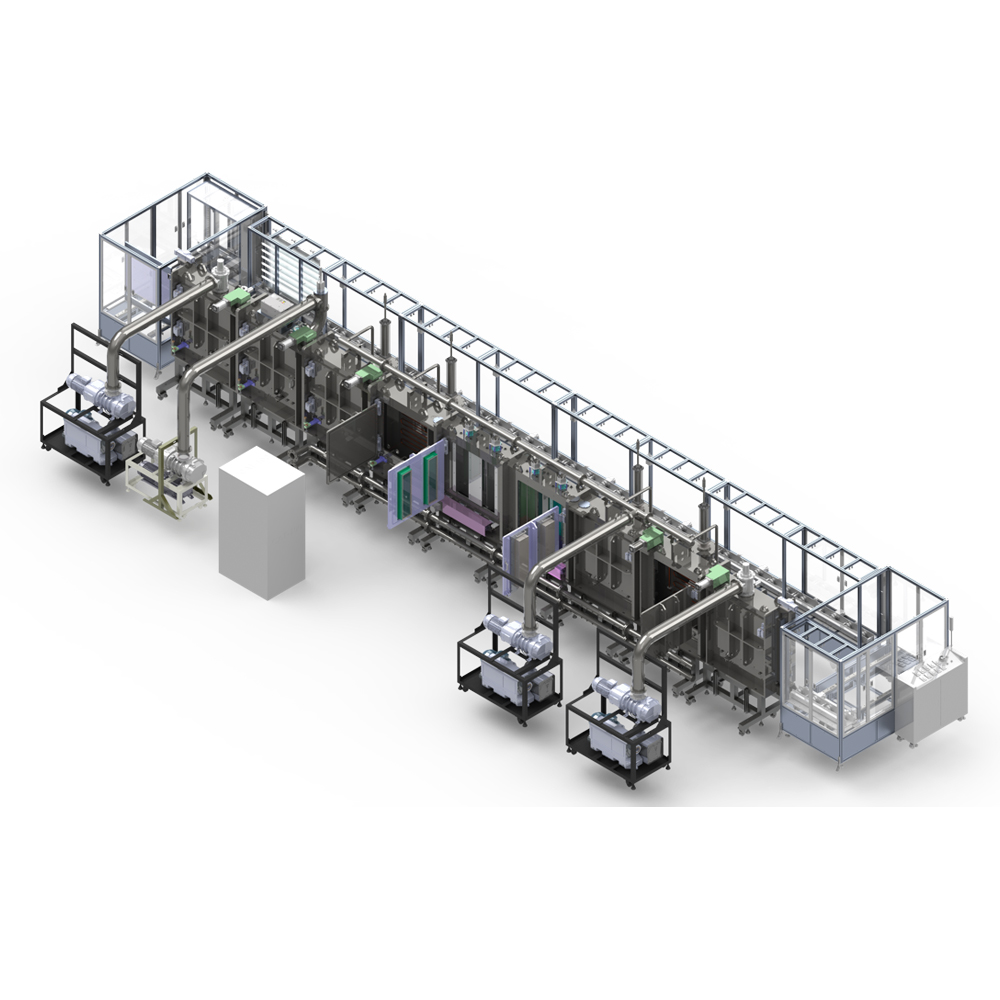

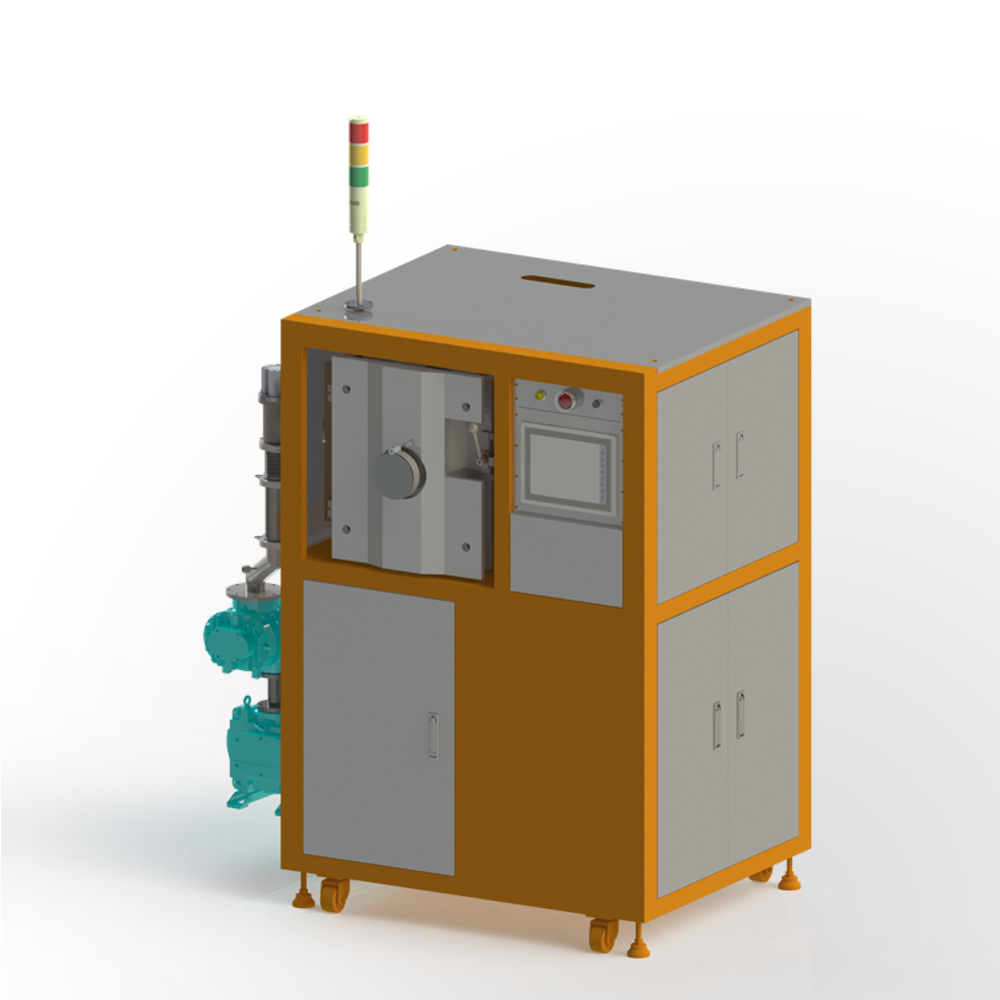

In Line sputter system. ( Tile 7 degrees).

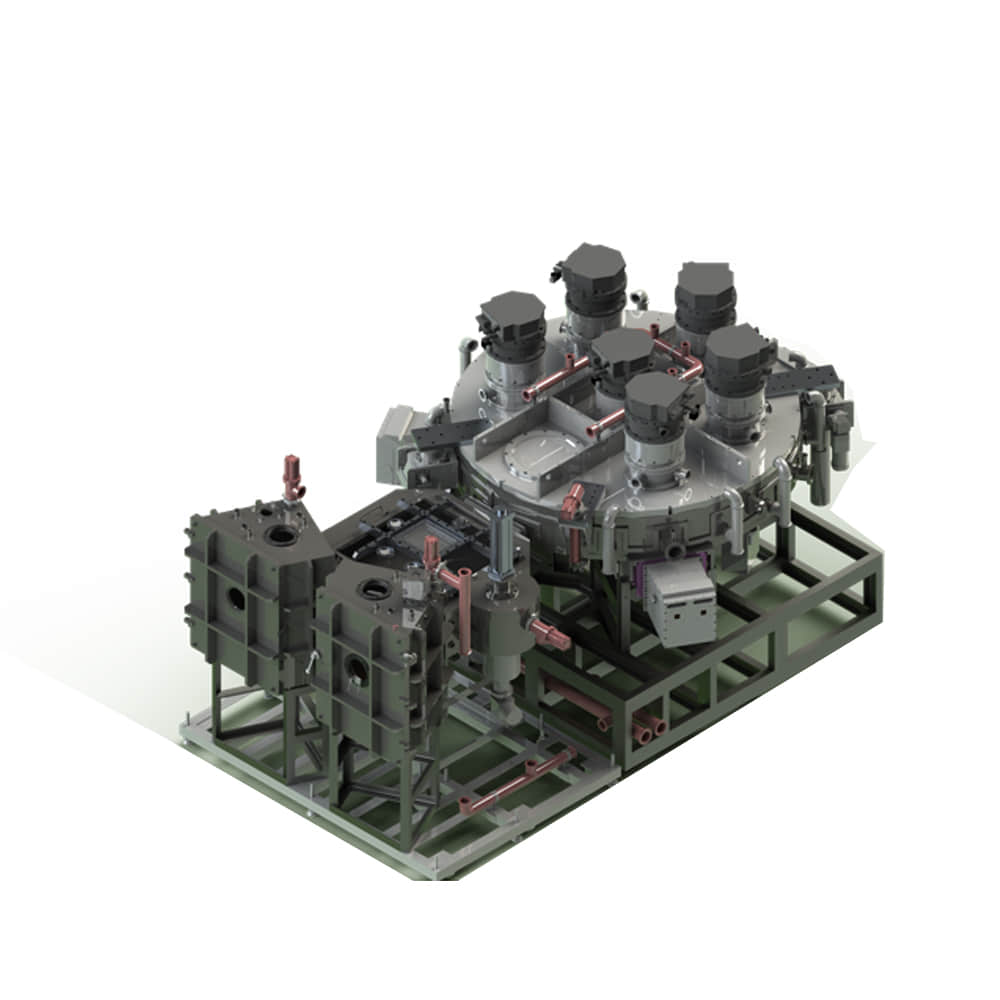

- Category : Vacuum sputter system, Vacuum system

- Feature of product:

- The plasma cleaning process is combined .

- The trolley transfer at an angle of 7 degrees, and the whole substrate can be coated without clamp the substrate.

- The upper part of the trolley adopts a non-contact (maglev) design, and the lower part adopts a friction rod to cooperate with the vacuum ferro for stable transmission.

- Shorten the trolley spacing and increase the utilization efficiency of target coating.

- The substrate can be fully coated and has the advantages of low PARTICLE process.

- It can cooperate with the auto-handing pick-and-place film and CIM plant planning.

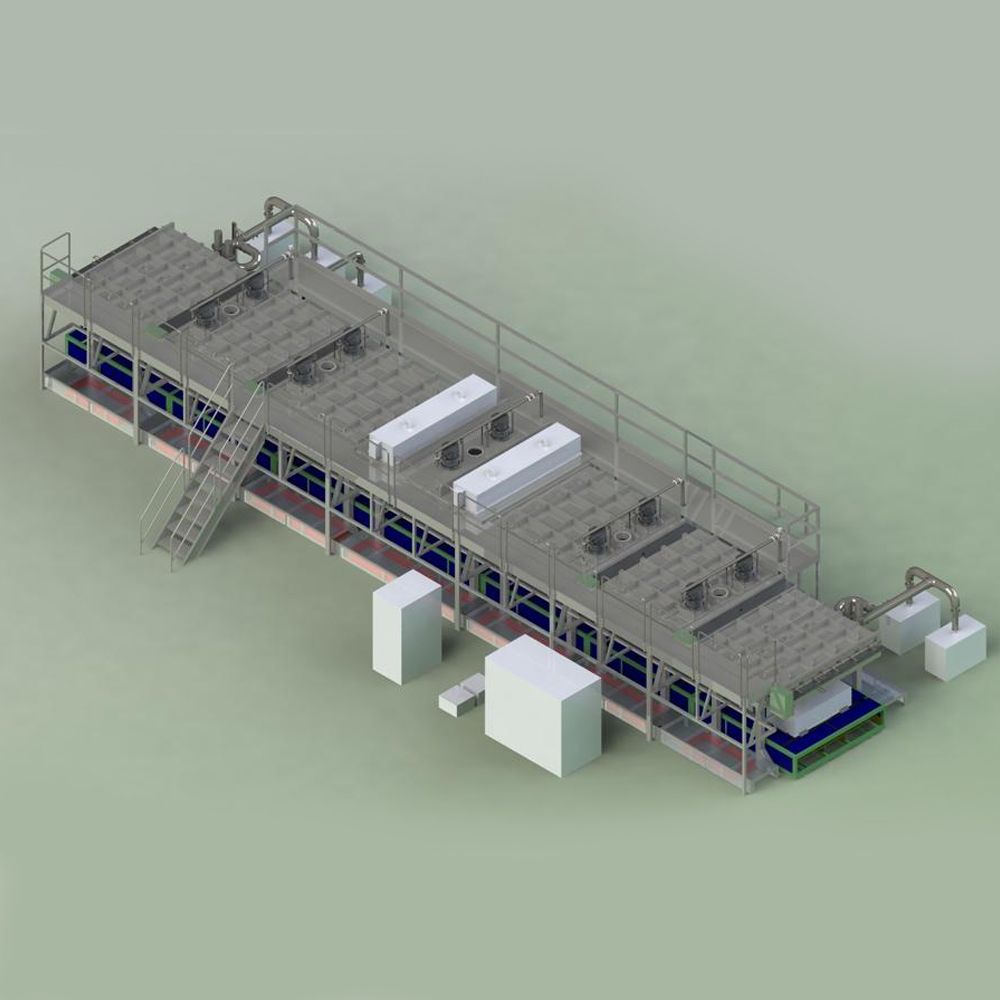

- The operating platform is established to facilitate equipment maintenance.

- Customized coating effective area and specification structure to meet industrial process requirements.

- Process and industry:

- Metal sputter process / reactive sputter process / oxide sputter process

- BSITO / solar cell / color coating and other industries.

- Product Gallery:

- Related: